- Home

- Production

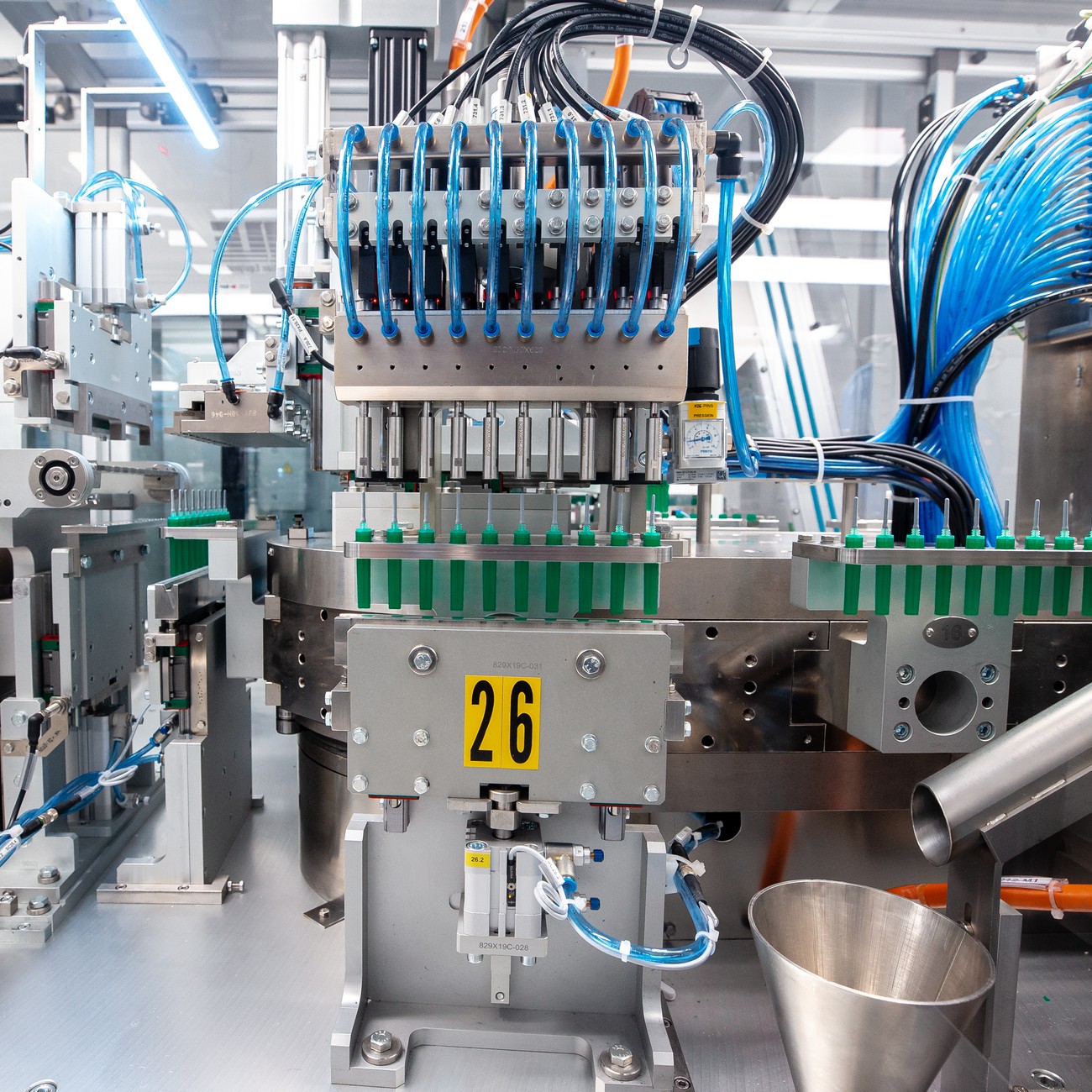

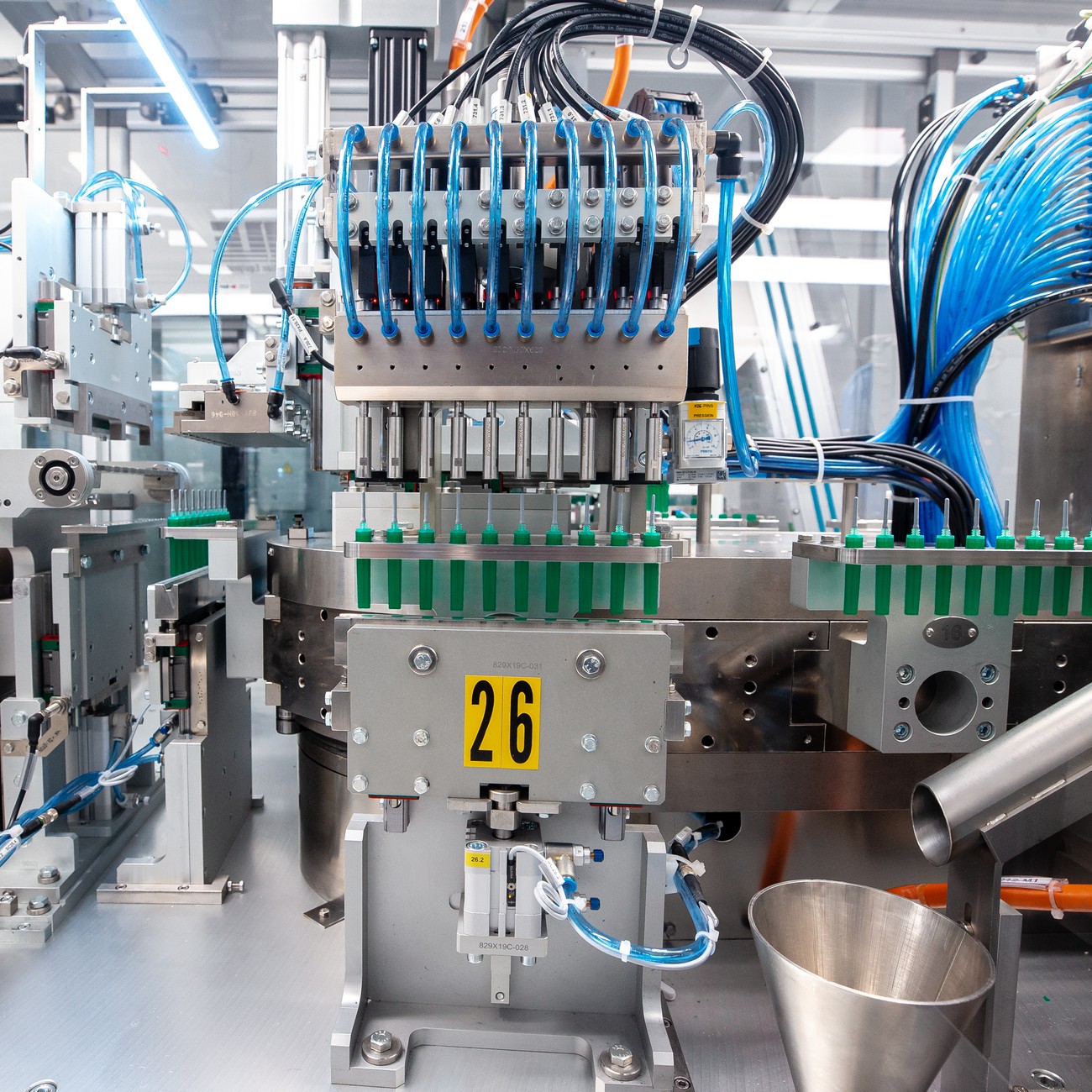

Swiss and Japanese equipment is installed in the molding section. One machine makes the tube body, the other - caps for vacuum tubes, three next machines fabricate plastic components for double-ended needles, and the sixth machine molds the holders.

The tube assembly line is unique in the world, developed together with German specialists especially for Granat Bio Tech.

The system automatically selects semi-finished products for assembly and analyzes the stock balances. The components are recorded in the stock balance only after 24-hours storage. The system also monitors the separation of products by batches of raw materials.

Fully automated. Video monitoring stations installed at each stage assist the sorting of products.

When the pallet is loaded the boxes are transferred to the warehouse for sterilization.

All plastic components after molding must be kept in the warehouse for semi-finished products during 24 hours.